TOOLING SOLUTIONS

Windsor Mold Group Tooling Division brings 50+ years of manufacturing experience and expertise to every project that we engage in. Through investment in research, people, process development and technology, the Tooling Division provides innovative tooling solutions for complex applications to the global market. Windsor Mold has been the recipient of multiple awards proving our commitment to quality and service.

Multi-color Molds (Reverse, 2 and 3 Station)

Multi-component Technology (2 and 3 Component)

Vertical and Horizontal Rotary Molds

Stack and Transfer Molds

In-mold Decoration (Textile)

Interior Trim Molds (Instrument Panels, Components and Garnishes)

Exterior Trim Molds (Fascias, Grilles and Painted Trim)

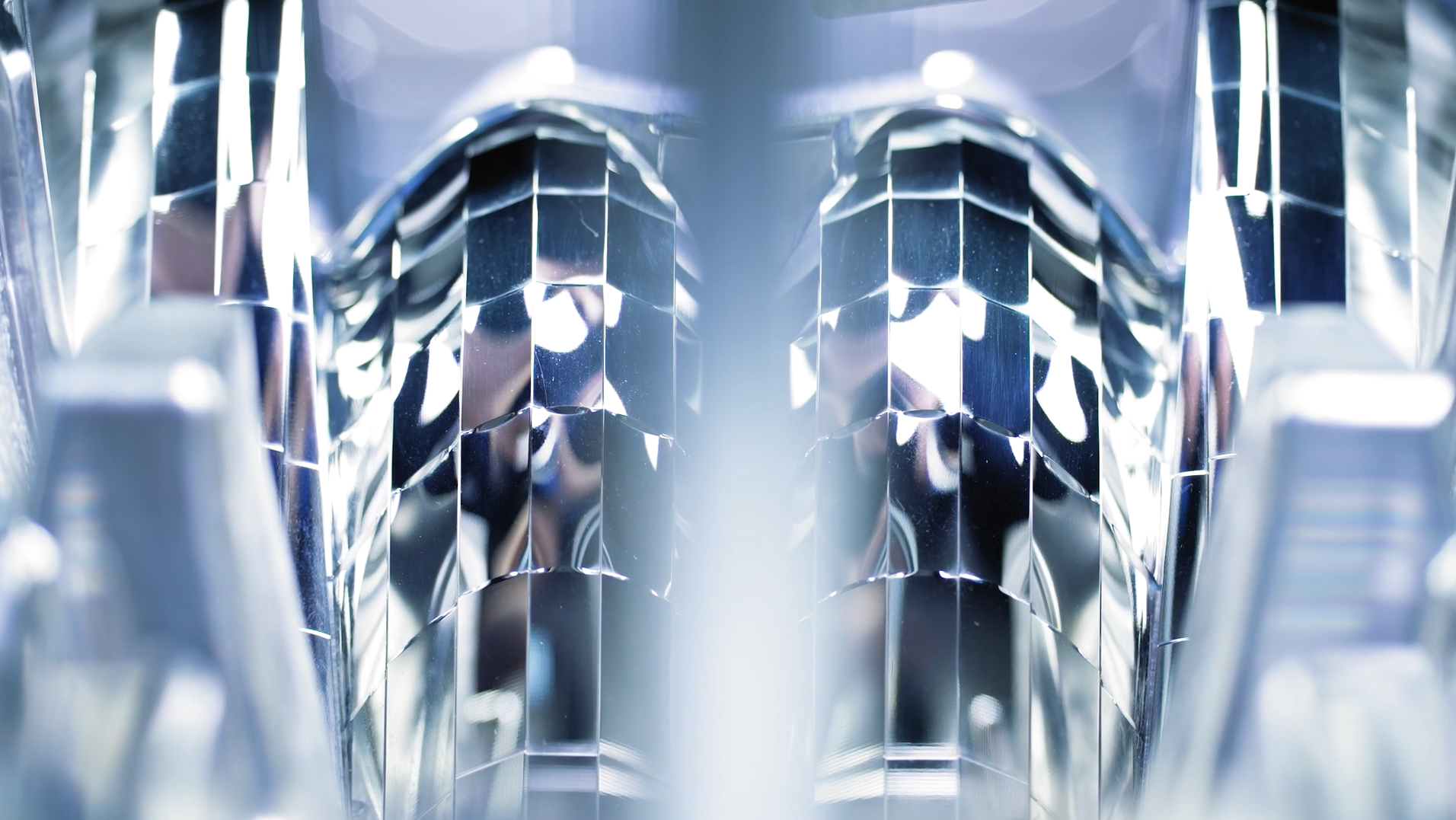

Lighting Molds (Interior / Exterior)

Light Pipes (Interior / Exterior)

Optical Inserts (0.05mm min. radius)

BMC Tooling (Bulk Molding Compound)

EOAT Tooling, Fixtures, Gauges

Prototype Tooling

Advanced Engineering / Feasibility

Product Design Support

Virtual Analysis and Simulation Support (Moldflow, FEA)

Class A Polishing (SPI #1)

CMM with Laser Scanning Technology

24/7 Full Service Emergency Support